how does a miniature circuit breaker work

How a Miniature Circuit Breaker (MCB) Works

Miniature Circuit Breakers (MCBs) are primarily categorized by their protection principle into thermal-magnetic and hydraulic-magnetic types. They are also distinguished by current type into DC MCBs and AC MCBs (also called Miniature Circuit Breakers). This article uses the AC thermal-magnetic MCB as an example to explain its operation, working principle, operating environment, and maintenance.

Working Principle and Operation of an MCB:

-

Switching the Circuit: An MCB connects or disconnects the power supply line via manual or remote operation of its mechanism. Moving the operating handle activates the mechanism, which connects or separates the moving and fixed contacts, thereby controlling the circuit's on/off state.

-

To reliably perform this function under various conditions, MCBs must meet specific electrical ratings, such as:

-

Rated Insulation Voltage (Ui): 500/600V

-

Rated Impulse Withstand Voltage (Uimp): 4kV

-

Power-Frequency Withstand Voltage: As per standards (e.g., dielectric test voltage at industrial frequency for 1 minute).

-

-

The housing material, typically PA66 reinforced nylon, is chosen for its high dielectric strength, low dielectric loss, and good heat resistance.

-

The product design incorporates adequate electrical clearance, and terminal designs often comply with finger protection requirements.

-

-

Interrupting Short-Circuit Currents (Short-Circuit Protection): This is achieved by the electromagnetic trip unit. It consists of an electromagnet. Under normal current conditions, the magnetic field generated is too weak to overcome a spring force, so the electromagnet remains inactive. During a short-circuit, the current surges dramatically, creating a powerful magnetic field that instantly pulls an armature. This action triggers the mechanical release mechanism, causing the contacts to separate rapidly (within 0.1 seconds or less) via a spring, thus breaking the circuit. The higher the short-circuit current, the faster the trip time. Thermal-magnetic MCBs typically offer selectable trip curves like B, C, D, K, or Z(Learn more B, C, D, K, Z Curve info).

-

Interrupting Overload Currents (Overload Protection): This function relies on a bimetallic strip. The strip is made from two or three metals with different coefficients of thermal expansion bonded together. Under normal load current, the heat generated causes slight bending, but not enough to trip. During an overload (current above the rated value), increased heating causes the bimetallic strip to bend more significantly due to the unequal expansion of the metals. Once the bending reaches a certain threshold, it pushes against a lever in the trip mechanism, causing the breaker to trip and open the circuit. The greater the overload, the faster the strip bends and the shorter the trip time.

-

Interrupting Fault Currents (Breaking Capacity): Breaking capacity is a critical performance indicator for MCBs.

-

Rated Ultimate Short-Circuit Breaking Capacity (Icu): This is the maximum short-circuit current that the MCB can successfully interrupt under specified test conditions (voltage, current, power factor). After this test, the MCB is not required to carry its rated current. The test sequence is O-t-CO.

-

Rated Service Short-Circuit Breaking Capacity (Ics): This is a breaking capacity value (typically a percentage of Icu) under specified test conditions. After interrupting this current, the MCB must still be capable of carrying its rated current normally. The test sequence is more rigorous: O-t-CO-t-CO. Subsequent verification includes trip characteristics and temperature rise tests.

-

Rated Short-Time Withstand Current (Icw): This is the maximum current the MCB can carry without damage for a specified short time (e.g., 0.05s to 1s). It assesses the MCB's electrical and thermal stability against electromagnetic forces and heat, primarily for Type B (selective) circuit breakers.

-

MCB Operating Environment:

-

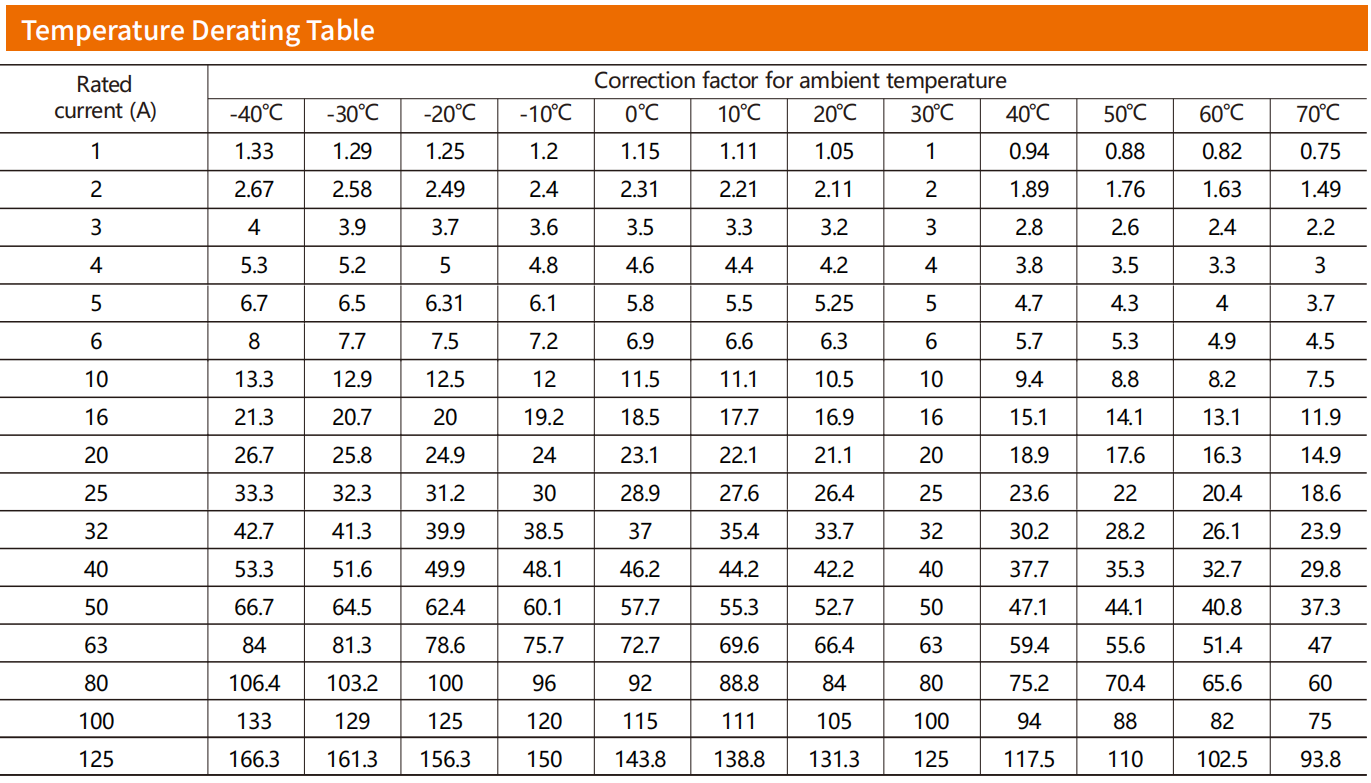

Ambient Temperature: Standards like IEC 60898 specify an operating ambient temperature range typically from -5°C to +40°C, with an average over 24 hours not exceeding +35°C. However, actual application environments can be wider (e.g., -40°C to +55°C). In such cases, it's crucial to consult the manufacturer for temperature compensation data,s, as extreme temperatures can affect the thermal trip characteristic. For instance, ambient temperatures above 40°C can lead to a 5-8% reduction in breaking capacity per 10K temperature rise.

-

Ambient Humidity: Humidity requirements are often related to temperature per standards (e.g., IEC 61439-1). For indoor equipment at 40°C, relative humidity should not exceed 50%. It can be higher at lower temperatures. MCBs are typically tested under damp heat conditions (e.g., 40±2°C, 93±3% RH) to ensure reliable operation in normal humid environments. For persistently high humidity (>95%) or outdoor use, special design features (drainage holes, internal heating, higher IP rating) may be necessary.

-

Altitude: High altitude significantly impacts MCB performance due to thinner air, requiring derating.

-

Effects: Reduced air density leads to poorer arc quenching and cooling, potentially lowering breaking capacity (Icu, Ics) and increasing operating temperature. It also reduces dielectric strength, potentially necessitating larger creepage/clearance distances.

-

Derating: Parameters like rated current, insulation voltage, and breaking capacity must be reduced using manufacturer-provided altitude correction factors.

Taking the ETEK, ETM1-63 circuit breaker as an example, the derating factors at different altitudes are as follows:

-

Design/Selection: For high-altitude applications, select MCBs specifically designed or certified for such use, ensure adequate electrical clearances are maintained (increased per standards like GB/T 16935.1), and consider enhanced cooling or more frequent maintenance.

Altitude Derating Factor Table from ETEK brand MCB Altitude (m) Rated working current Rated power frequency withstand voltage Rated impulse withstand voltage Rated short-circuit breaking capacity and electrical life 2000 1.00 1.00 1.00 1.00 3000 0.99 0.89 0.89 0.83 4000 0.96 0.80 0.80 0.71 5000 0.94 0.73 0.73 0.63

-

MCB Inspection and Maintenance:

MCBs can experience wear and aging, potentially compromising electrical safety. Regular inspection and maintenance by qualified electricians are essential.

Maintenance Steps:

-

Preparation: Ensure complete power isolation. Gather appropriate tools (screwdrivers, wrenches) and Personal Protective Equipment (insulating gloves, safety glasses). Review the MCB's specifications.

-

Visual Inspection: Clean the exterior. Check the housing for cracks, damage, or severe discoloration. Ensure labels and markings are legible.

-

Functional Considerations: Be aware that the breaking capacity may degrade over time after multiple interruptions. Regular testing might be necessary to verify performance.

Q1: Causes of MCB Aging?

-

Long-Term Use and Mechanical Wear: Components like contacts, springs, and operating mechanisms wear down from repeated operation. Contact erosion increases resistance, leading to overheating. Springs can lose tension.

-

Environmental Factors:

-

High Temperature: Accelerates the aging of insulating materials and can cause thermal stress on metal parts.

-

Humidity: Can cause corrosion of metal components and degrade insulation properties.

-

Dust and Contamination: Impairs heat dissipation and can interfere with the movement of mechanical parts.

-

-

Electrical Stress: Frequent overcurrents (overloads) and short-circuits cause thermal and mechanical stress on the bimetal strip, electromagnet, and contacts, accelerating aging.

-

Product Quality and Lack of Maintenance: Inferior materials or manufacturing shorten lifespan. Inadequate maintenance (e.g., not cleaning, ignoring loose terminals) fails to identify and address issues early, hastening deterioration.